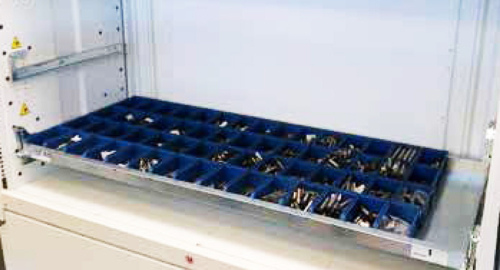

Modula Lift is sure to revolutionise your workflow. Over 30 years of experience and continuous research have enabled us to develop a highly technical product in which safety and intelligent design are the main focus. Which accessories do we recommend for you? Alphanumeric LED Bar, Laser Pointer, Put to Light, Tray Dividers, Partitions and Extensions and Robot Interface.