A single Modula warehouse is enough to instantly recognise the advantages you will gain:

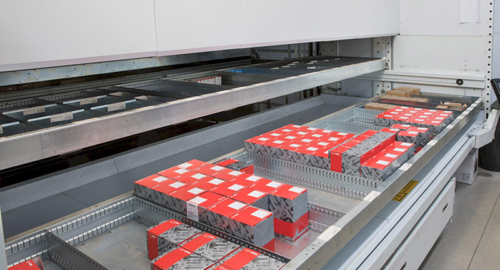

• Reduced use of floor space effective use of vertical space, up to 16 metres in height. In other words, this means new space is made available on the floor for other functions, or lower rental and/or management costs.

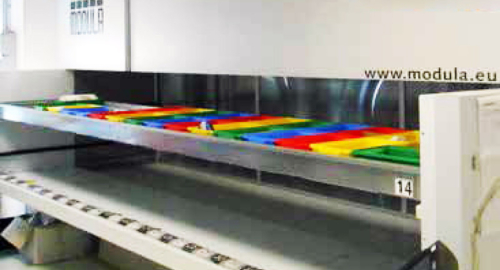

•Automatic optimisation of storage space, with dynamic tray height storage: you will no longer have to waste precious time figuring out the best distance between one shelf and the next. And above all, you won’t waste space with shelves that are too wide.

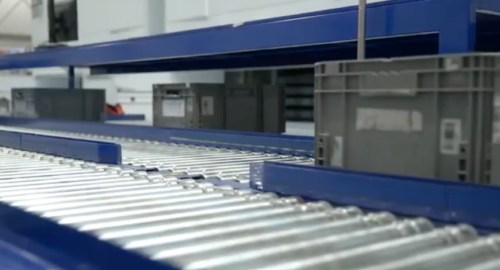

• Picking throughput is increased by the automated system which moves the trays and avoids your operators having to move around the warehouse looking for items. With the dual delivery level, wait times in production are reduced to virtually zero.