Put to Light Solutions

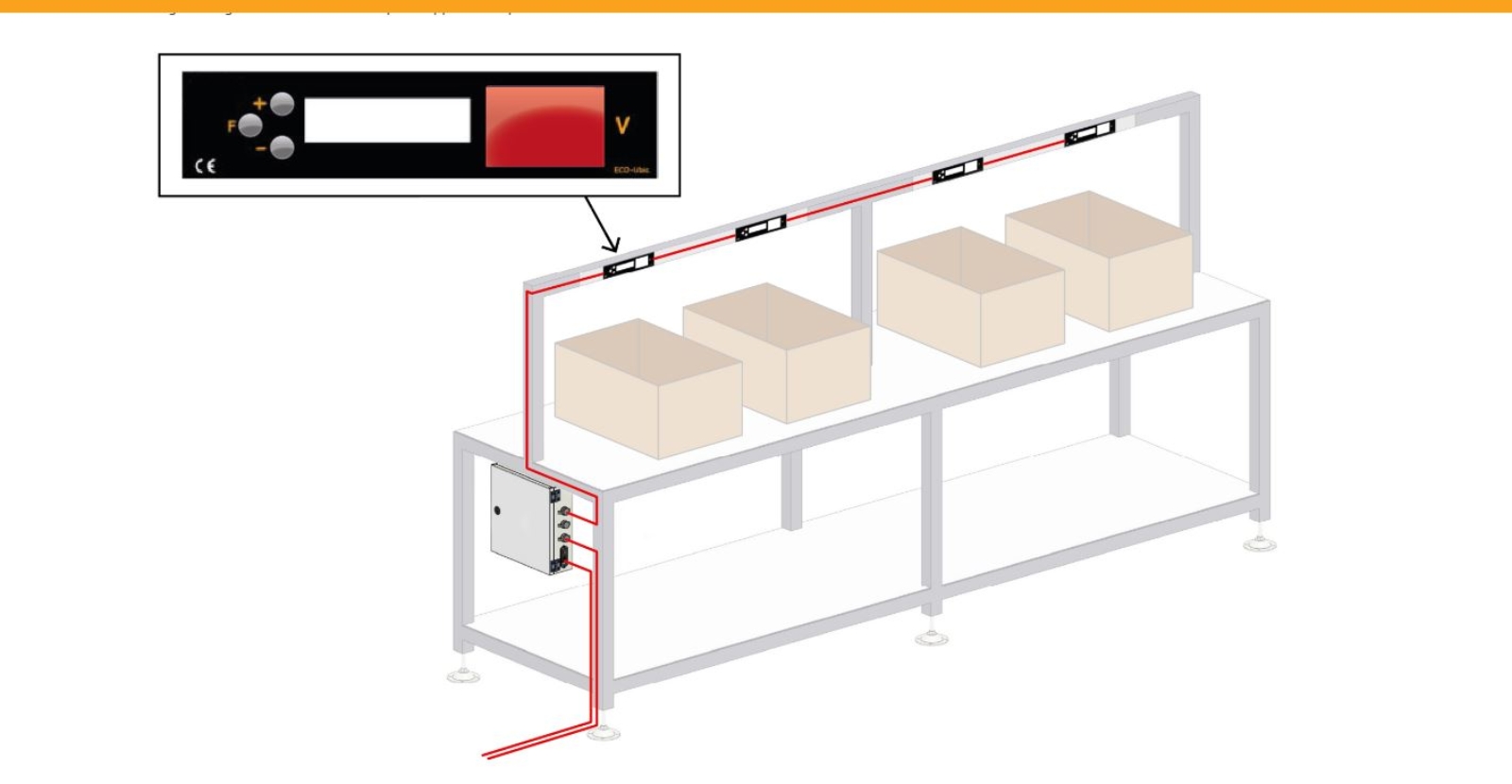

Advanced picking systems that can be seamlessly integrated with our vertical automatic warehouses to enhance operational efficiency.

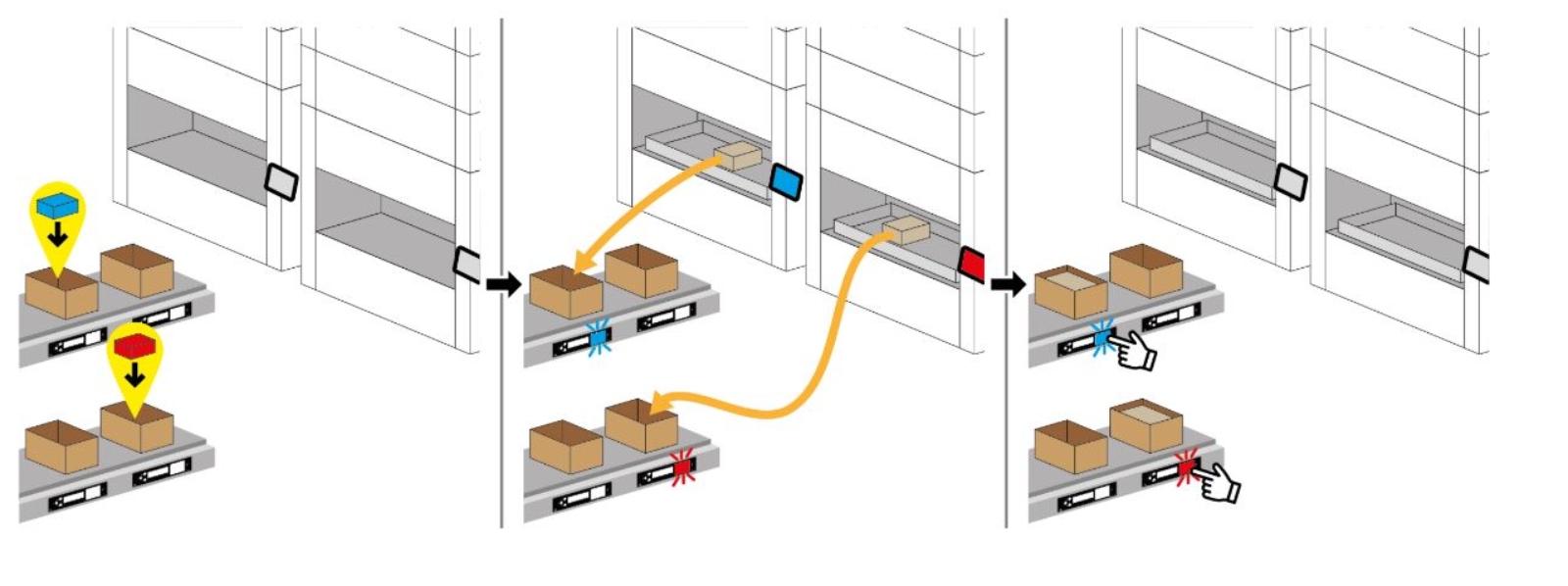

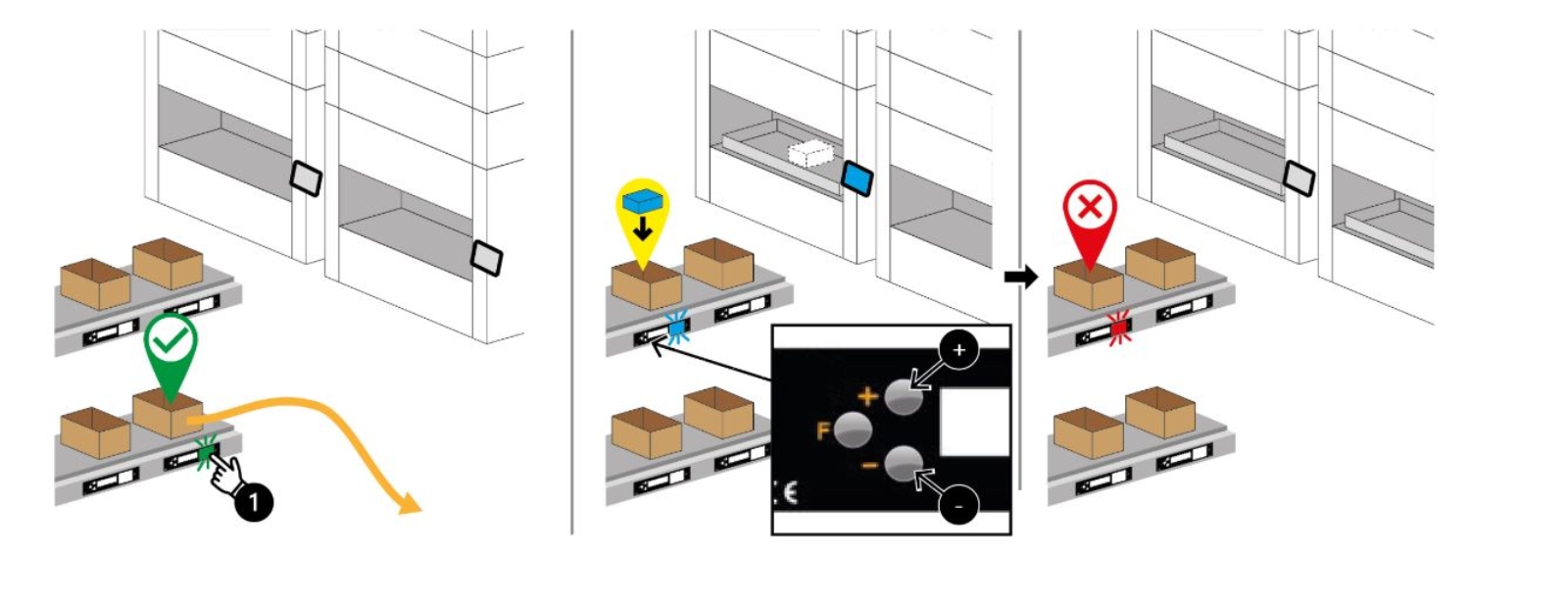

Equipped with cutting-edge technologies, these systems make the picking process faster, easier, and more accurate than ever. In vertical warehouses, where every centimetre of space counts, these advanced picking systems allow items to be retrieved in seconds, significantly reducing errors and improving delivery times. Tools like touch screen displays, put to light assisted picking technology, wearable devices, and pocket monitors simplify and streamline the process, making it more intuitive and productive.

The results? Greater efficiency, reduced operator stress, and a drastic improvement in the management of daily operations. For picking that’s truly smart!