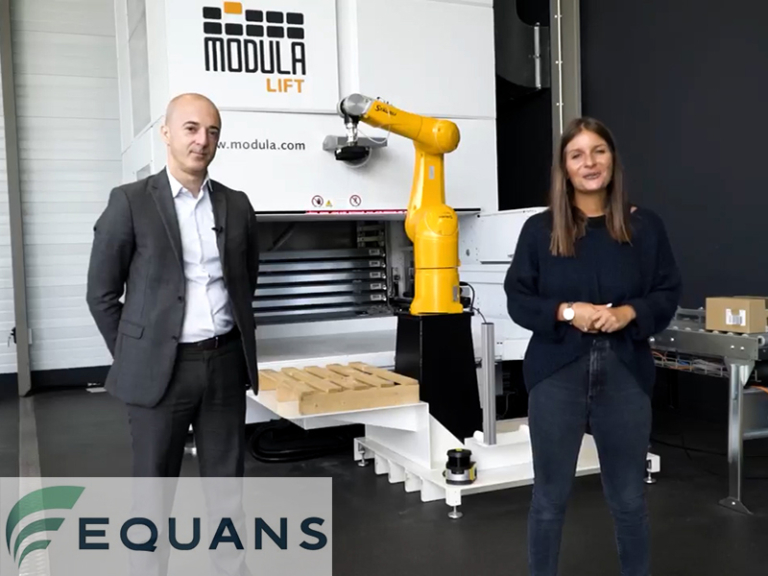

ABB is a leading multinational automation and electrification company. Artificial intelligence systems, drives and motors, digital solutions and electrification services are part of its portfolio, which also boasts a wide range of business automation solutions for industries. With ABB it is possible to create integrated automation solutions of the highest level and integrate them with Modula automated warehouses using the robot interface kit.

Masinara, a Bologna-based company that manufactures components for rolling shutters, is an example of the application of ABB’s robotic integration with Modula automatic warehouses. The Modula warehouses were installed in series on two sides, with a conveyor belt in the middle where the ABB robot moves. This is a case of a 100% robotic island, which is completely autonomous and does not require the intervention of a warehouse operator.