Modula can be defined as a visionary company, with the digitalization of processes as one of its strengths.

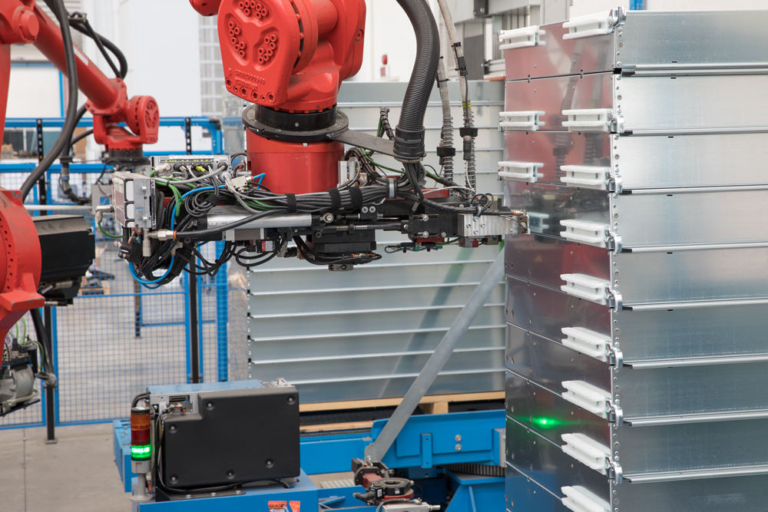

Over the years, we have opted for 100% Modula production according to a robust strategy of automation of production lines as well as insourcing of manufacturing and process know-how. This has made us stronger and stronger in terms of product quality, competitiveness in the market and knowledge of processes.

We have chosen to focus on the vertical production of a single type of product and have always dedicated a great deal of resources to research and development. We have therefore developed a wide range of models and possible configurations at our warehouses.

Foresight in investment has resulted in the dedication of over €150 million to the creation of state-of-the-art production facilities in Italy, the United States and China.