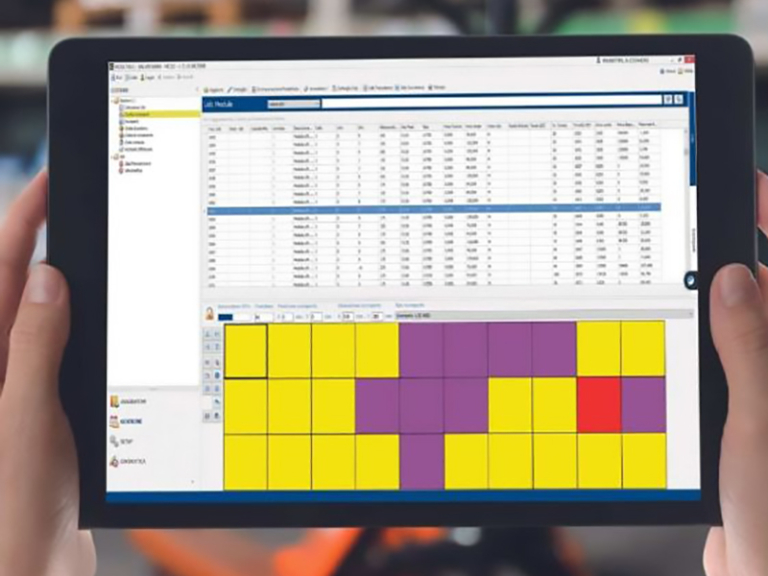

All this data is an invaluable source for any company’s supply chain; through its analysis, it is possible to better understand the logistical flow of the entire warehouse (of which Modula’s storage systems are only a part) in order to optimise its efficiency and thus reduce waste and management costs.

With its WMS management software, Modula ceases to be just a vertical automated warehouse storage system and becomes a true IoT ring, which is then able to transmit information to the company management system or interface with other technologies such as anthropomorphic robots, AMR autonomous driving systems, automatic conveyors and much more.

Modula WMS is designed not only as a perfect complement for the management of the entire range of Modula warehouses, but can also be used as a tool for the management of traditional warehouses or manual storage areas where data monitoring and greater control of flows are required.