Climate change is one of the most urgent and complex challenges of our time, with a significant impact on a wide range of sectors, one of which is agriculture. Increased temperatures, variations in rainfall and the escalation in the frequency of extreme weather events are challenging the ability of many crops to ensure productivity, quality and sustainability.

Resulting in the need for innovative and sustainable solutions, which can optimise and guarantee stable and quality production regardless of the external environmental conditions. Vertical farming (especially indoors) is gaining ground – amidst this scenario – as a concrete and promising solution, providing the possibility of working in completely controlled environments, independent of external conditions. This optimises the use of space and reduces environmental impact.

Exploiting micropropagation and indoor vertical farming to address climate challenges

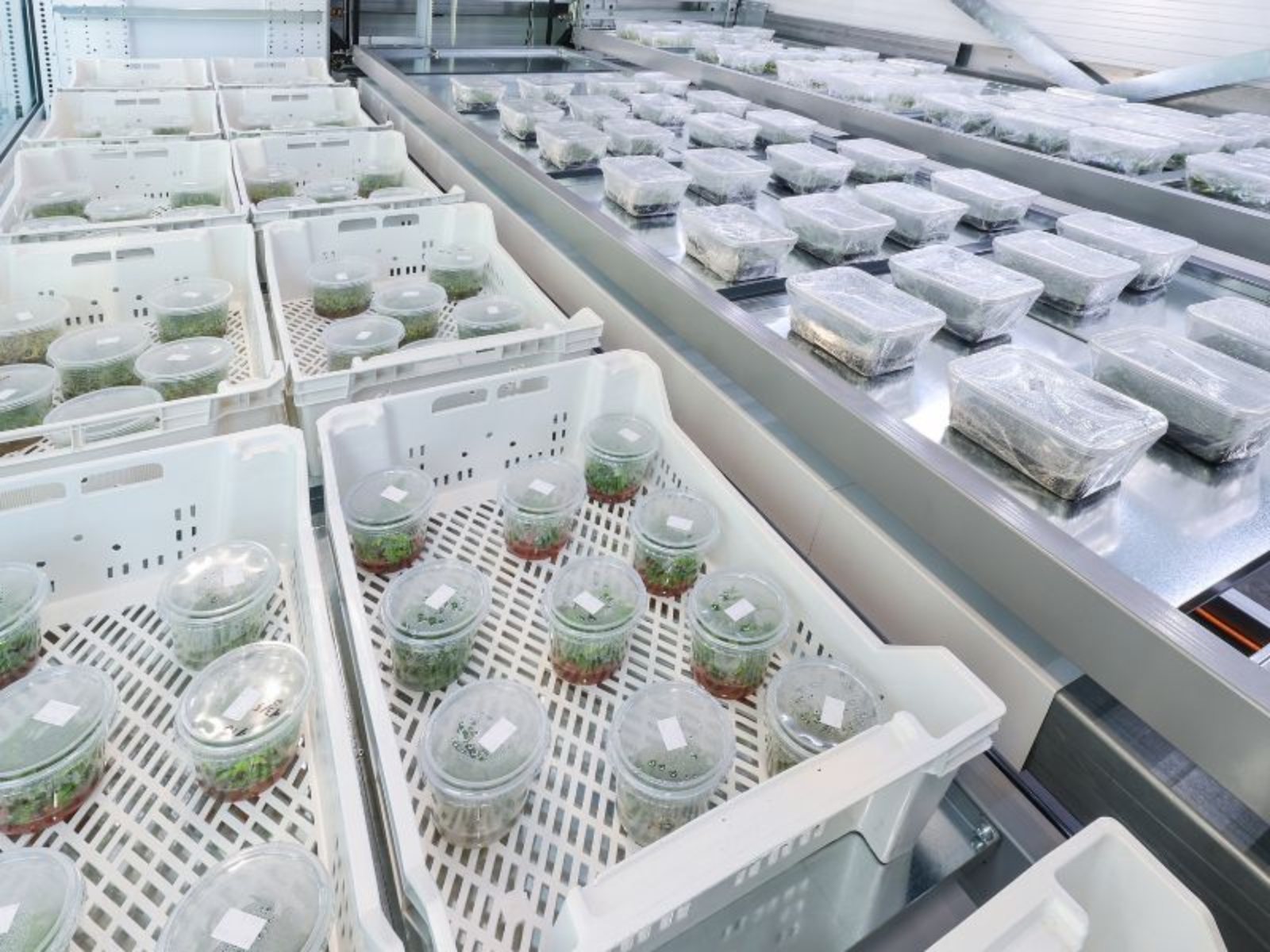

Within this new frontier for agriculture, micropropagation plays a very important role. In fact, it is an advanced cultivation method that allows plants to multiply rapidly in a sanitised and controlled environment.

It is clear that the success of micropropagation depends almost entirely on the precise control of fundamental environmental factors such as temperature, humidity and light intensity. These are parameters that must be kept within optimal values to ensure healthy growth and even development of the plants.

This careful and precise control provides several benefits, including:

- Very good production quality

- Accelerated production time

- Clean and contamination-free products

- Stable, genetically high-quality products

Therefore, combining micropropagation and vertical farming opens up new horizons for modern agriculture, which can be summarised in the following example.

Micropropagation – carried out using a solution such as the Modula Biotech Tower – guarantees healthy, high-quality plant material. Subsequently, these seedlings can be grown in dedicated indoor environments such as the Modula Farm – the solution designed for controlled vertical farming – which guarantees optimal conditions for crop growth and development.

With these advanced technologies it is possible to maximise yield, sustainability and productivity, effectively tackling the challenges of climate change and the growing global demand for healthy and sustainable food.

Modula Climate Control, Farm and Biotech Tower: advanced technology for environmental control and refrigerated storage

Modula technologies are now a benchmark for companies in a broad range of sectors, offering systems designed to meet the most demanding requirements for environmental control and efficient space management.

For example, Modula Climate Control is a vertical automatic warehouse equipped with a sophisticated thermal insulation and refrigeration system designed to guarantee stable and optimal environmental conditions. The structure is clad with polyurethane foam insulation panels that create an effective thermal barrier, reducing energy loss and consumption.

Inside, temperature and humidity probes constantly monitor the microclimate, ensuring accurate, real-time control. There is also a temperature regulation system in the loading and unloading area: if significant differences are detected with respect to the internal environment, the tray closing is temporarily delayed to avoid temperature fluctuations that could compromise the quality of the stored material.

This technology is perfect for the storage of biotech and plant material, where temperature-controlled storage is essential to maintain the integrity and viability of crops.

Modula Farm and Biotech Tower: modular solutions for vertical indoor farming and micropropagation

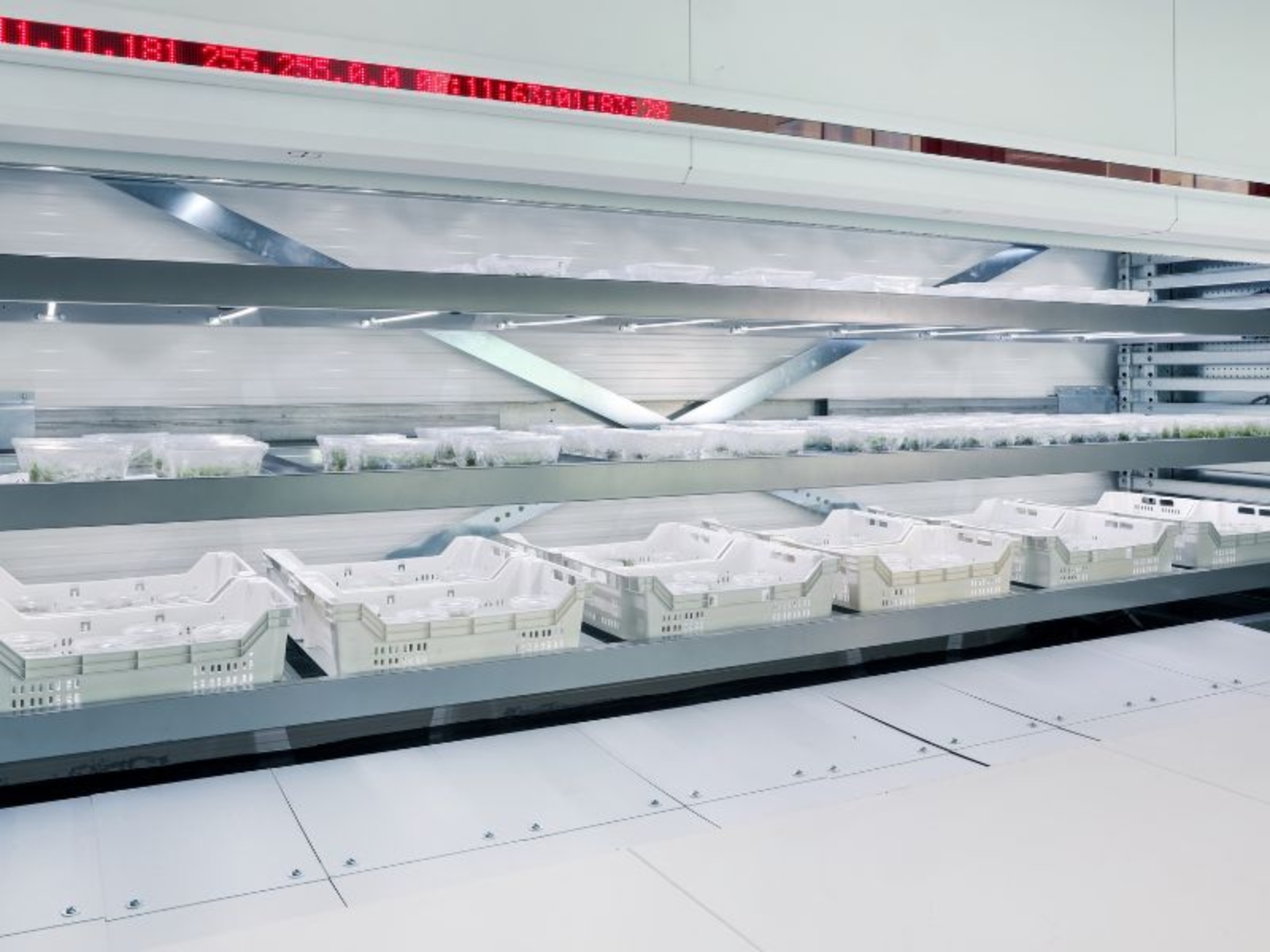

Modula Farm represents the ultimate technological solution for vertical indoor cultivation: it is designed to guarantee optimal growing conditions by means of a system that integrates irrigation equipment and precise environmental control. This vertical automatic warehouse, with a height of up to 10 metres, makes it possible to maximise the space available and cultivate large quantities of plant material efficiently and sustainably.

Thanks to different tray arrangement configurations Modula Farm offers extraordinary storage capacity:

- up to 5,940 trays in arrangement 1,

- 6,600 trays in arrangement 2,

- and up to 11,800 trays using the maximum depth of the structure.

Each tray can accommodate up to 40 seedlings, and the capacity can be further enhanced by opting whether or not to use dividers between the compartments. In this way, arrangement 1 can reach a maximum of 5,957 trays, while arrangement 2 can reach up to 6,661 trays.

Both arrangements, taking advantage of the maximum depth, reach 11,906 and 9,917 trays.

The same optimisation principle can be applied to the storage of mason jars, which can be arranged in four different configurations, with or without dividers, to further increase the capacity and flexibility of space utilisation.

Furthermore, Modula Farm is equipped with an integrated irrigation system, an essential element that differentiates it from the Modula Biotech Tower, which is designed primarily for micropropagation and nursery activities in laboratory or production environments. In fact, the Biotech Tower is a special solution that focuses on the control of environmental parameters such as temperature, humidity and lighting to promote optimal growth of plant material.

In short, Modula Farm offers a complete system for efficient and scalable vertical cultivation, while the Biotech Tower represents a specialised environment for micropropagation, both key elements in the Modula ecosystem dedicated to innovative and sustainable agriculture.

| Features | Modula Farm | Modula Biotech Tower |

| Fertigation system | Present, integrated to ensure optimal water and nutrient supply | Absent, not planned for micropropagation and nursery activities |

| Use of CO₂ | Yes, essential to maximise production | Generally not necessary |

| Type of lighting | High light intensity with full white or (optional) pink spectrum | Low intensity lighting, mainly cold white or neutral |

| Biological control and beneficial insects | Yes. Use of bumblebees for pollination and carnivorous insects for biological control is recommended. Natural treatments possible in bays | No. Priority is sanitisation of surfaces and air to prevent contamination |

| Day/night performance difference | Present and managed to optimise crop growth | Minimal physiological fluctuations of the plants |

| Main applications | Cultivation of plants used as food, aromatic plants, and for other agricultural uses | Nursery activities (grafting, transplanting), advanced micropropagation, insect breeding, mushroom cultivation |

Innovating agriculture with Modula: solutions that deliver efficiency, sustainability and productivity

Facing the challenges imposed by climate change and the growing demand for sustainable, high-quality agricultural production requires innovative, reliable and high-performance technological solutions. Micropropagation and vertical farming represent two cornerstones of this transformation, capable of ensuring efficiency, resource savings and high quality standards.

Thanks to state-of-the-art technologies that integrate precise environmental control with intelligent space optimisation Modula solutions are positioned as a strategic partner for companies and laboratories that wish to make sustainability and innovation their strengths. The Modula Farm and Biotech Tower provide perfectly managed, flexible and scalable environments, ideal for successfully supporting new cultivation methods.

Investing in these technologies not only means improving the productivity and quality of crops, but also embracing a more responsible and resilient agricultural model capable of responding effectively to the environmental and market challenges of today and tomorrow.

Exploiting automation to improve agricultural production

In the field of agriculture, automation and control of thermal insulation are the keys to more efficient and scalable production. Check out our article on how to exploit innovative solutions in logistics.