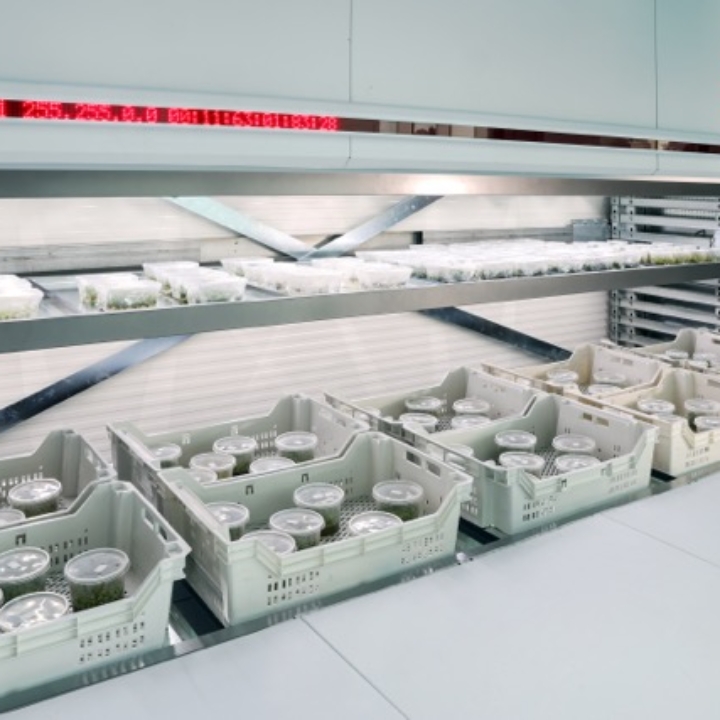

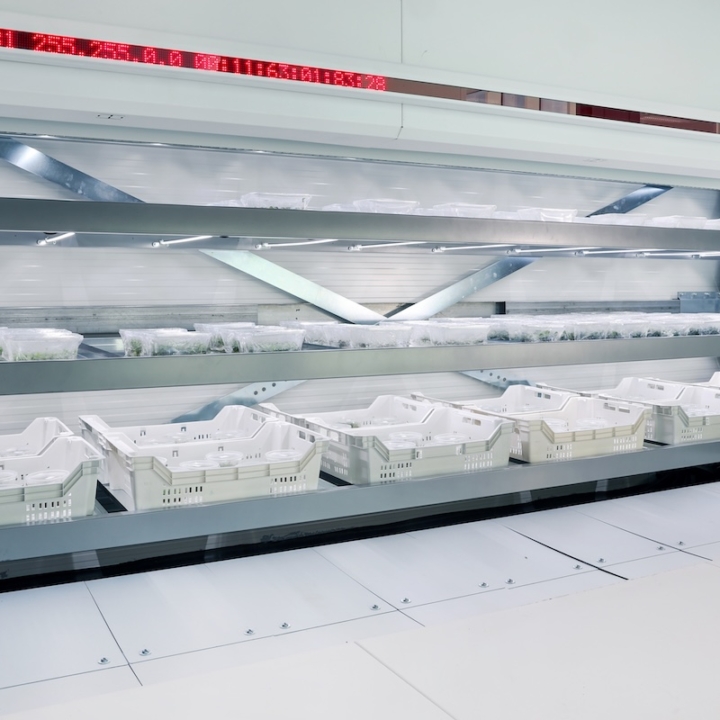

We tested our system through multiple trials in collaboration with various partners, starting from highly complex crops.

The result?

- Absolute production uniformity

- Total control of climatic and environmental parameters

- Greater efficiency, less waste, optimized yields