The Company: Royal Canin Korea, Quality and Safety in Pet Food through Controlled Production Processes

Royal Canin Korea, a leading player in the pet food industry, must guarantee extremely high production standards every day, both in terms of quality and safety, as well as customer service that lives up to the brand. To achieve this, logistics, production, and marketing play a fundamental role.

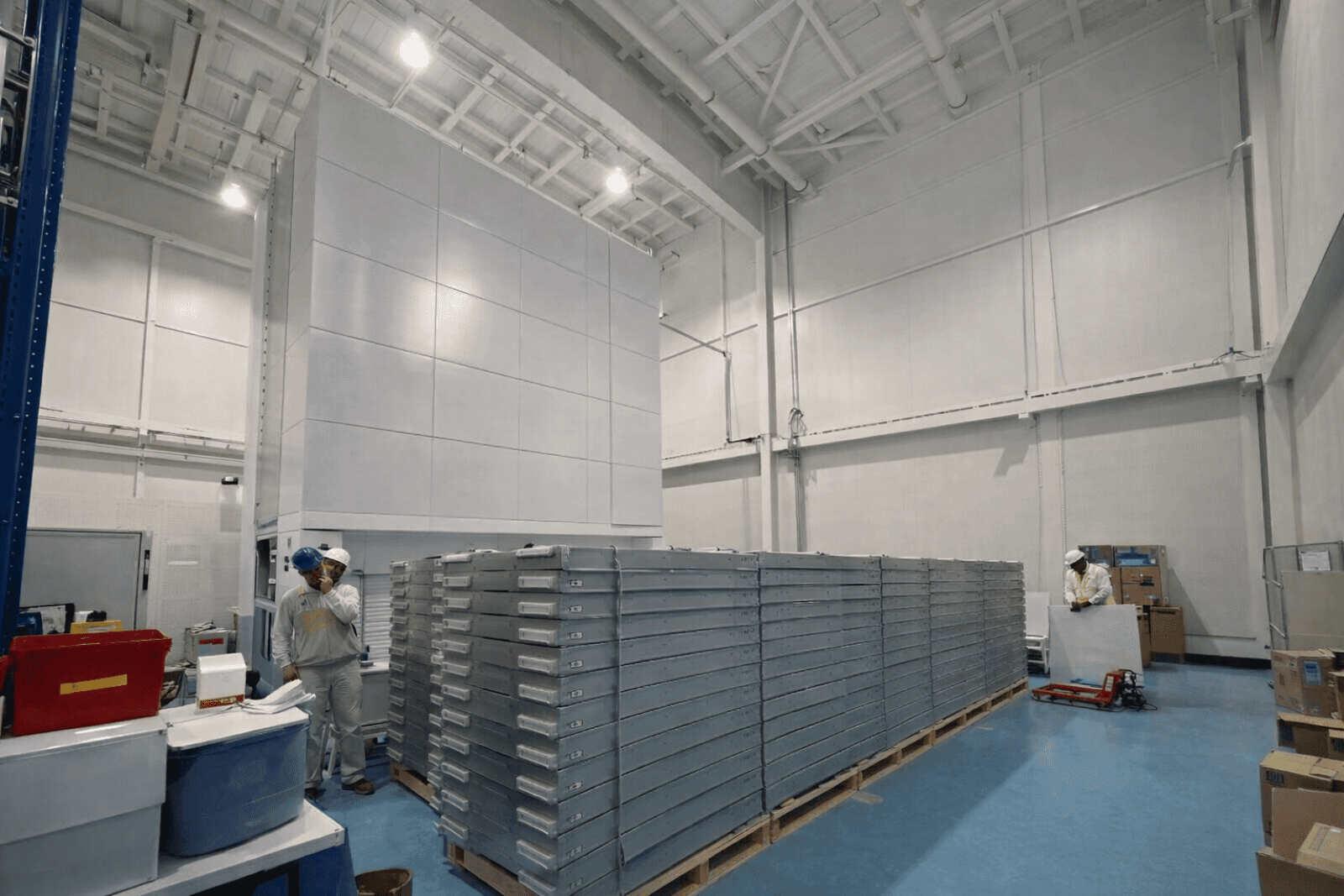

The Korean plant operates in a controlled environment compliant with Class 1000 clean room conditions, where order, cleanliness, and precision are essential elements. In this highly regulated context, the management of spare parts and raw materials for automation systems plays a strategic role in ensuring production continuity and efficiency.

The Challenge: Managing Spare Parts and Materials While Improving Safety, Ergonomics, and Efficiency

For such a significant operation, the stock of spare parts and palletized materials handled by forklifts presented several critical issues: retrieving a single component required using a forklift to reach inconvenient heights, causing ergonomic and safety concerns and negatively impacting overall efficiency. Over the years, there were also minor workplace accidents, incompatible with the high safety and cleanliness standards required by the production environment.

The Solution: Modula Vertical Lift Modules for Safe, Automated Storage

To address these issues, Royal Canin Korea chose Modula vertical lift modules, specifically a solution based on two Modula Lift ML50D vertical lift modules, each equipped with 71 trays. The system was enhanced with a laser pointer and a sliding console—accessories that make material picking even more intuitive and faster. Thanks to Modula automated tray storage systems, spare parts and components are now neatly organized, protected within a closed structure, and easily accessible without the use of forklifts, perfectly aligned with the requirements of a controlled production environment.

The Results: Greater Workplace Safety and Improved Operational Efficiency with Modula Vertical Lift Modules

After implementing the Modula vertical lift modules, the benefits were immediate and tangible. The drastic reduction in the use of heavy equipment led to a significant decrease in the risk of accidents at the production site, improving operator safety. At the same time, operational efficiency increased rapidly: spare parts for automated production systems are now easy to locate and retrieve in just a few moments, thanks to a practical, safe, and user-friendly storage system.

The result? A faster, safer, and cleaner workflow, perfectly aligned with the values and quality standards of Royal Canin Korea.

The Future: Royal Canin Korea Invests in Logistics Automation and Sustainability with Modula

Following the positive experience with Modula vertical lift modules, Royal Canin Korea looks to the future with the goal of continuing to optimize its logistics processes, focusing on solutions that combine automation, safety, and sustainability.

The collaboration with Modula represents a strategic step toward increasingly efficient material management, in line with the company’s high quality standards and a vision oriented toward continuous innovation.