Logistics is experiencing a transformation so profound, it can be described as a true technological revolution. A recent McKinsey report predicts that by 2030, more than 45% of logistics activities will be automated. This shift is being driven by the growing integration of robotics, artificial intelligence and advanced digital solutions. Meanwhile, the global market for Autonomous Mobile Robots (AMRs) is expanding rapidly, with an annual growth rate of 23.7% and an estimated value of 10 billion dollars by 2028.

What was once a competitive advantage for a few is now a necessity. Automation has become the key to thriving in markets that are faster, more complex and more global than ever before.

The Technologies Redefining Logistics

Today’s logistics revolution is powered by the convergence of robotics, AI and IoT. These technologies are no longer occasional support tools. They now work together to create an intelligent logistics ecosystem that adapts in real time to business needs.

- Collaborative Robots (Cobots) and Autonomous Mobile Robots (AMRs)

- Cobots support human operators by handling repetitive, physically demanding or hazardous tasks. This improves productivity, safety and overall working conditions.

- AMRs navigate warehouses independently, using advanced sensors and algorithms to avoid obstacles and transport goods without human intervention.

- Internet of Things (IoT)

- IoT links sensors, devices and machines across the supply chain, turning warehouses into connected ecosystems. Continuous real-time data gives companies full visibility, instant control and the agility to respond quickly to disruptions. Already widely adopted in e-commerce, retail and manufacturing, IoT enables more efficient, automated and sustainable operations that deliver measurable competitive advantages.

- Artificial Intelligence (AI)

- AI transforms large data sets into actionable insights, enabling fast and accurate decision-making. With predictive analytics, it optimizes inventory, forecasts demand, reduces errors and ensures greater efficiency and sustainability.

Modula: From Vertical Storage to a Complete Smart Logistics Ecosystem

For years, Modula has been a leader in compact and efficient vertical automated warehouses. Today, Modula represents much more. It is a fully connected ecosystem that integrates robotics, AI, IoT and advanced picking solutions. With Modula WMS, businesses gain a smart, flexible and connected partner in logistics.

Next-Generation Picking Solutions

Modula has designed innovative tools that make picking faster, more precise and virtually error-free, even when handling hundreds of orders at once.

- Mobile Picking App: An intuitive Android application that allows operators to manage picking on the go, supporting barcode scanning or device cameras for fast and simple workflows.

- Picking Station with Put to Light: A modular station that uses illuminated guides to direct operators quickly and accurately, increasing throughput while reducing errors.

- Pick to Color Cart: Each cart is color-coded to visually guide operators through order fulfillment, boosting both efficiency and accuracy.

These systems can be paired with wearable devices that confirm picks instantly through QR codes, ensuring fast and ergonomic operations.

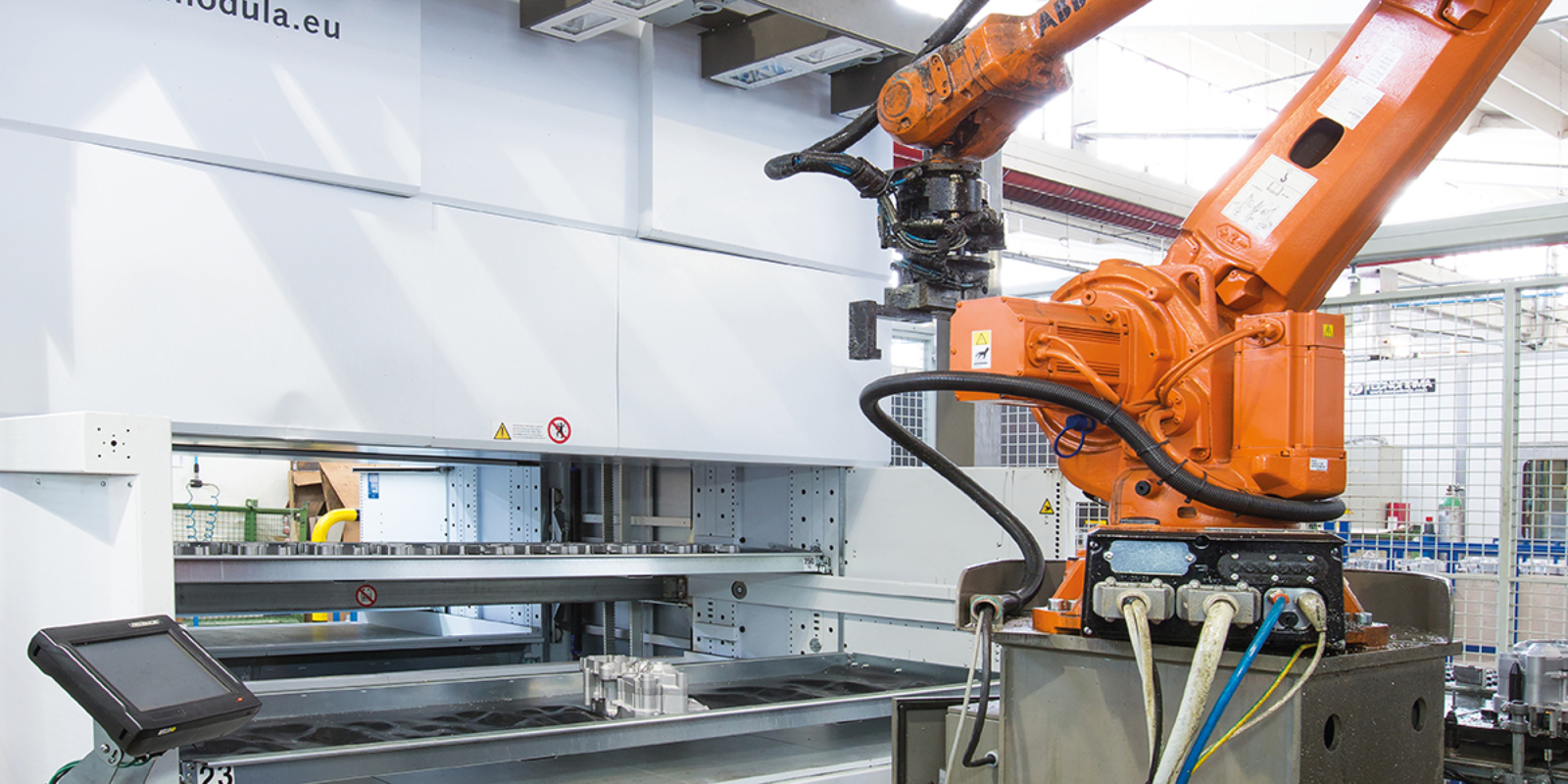

Robotics Integration for Seamless Automation

The real breakthrough comes with the integration of advanced robotics into Modula’s interconnected ecosystem. Through Modula WMS, vertical warehouses communicate intelligently with anthropomorphic robots, AMRs and other automated systems, even from different providers.

- Anthropomorphic Robots: Robots that handle repetitive tasks such as picking, packing and palletizing, freeing operators from physically demanding work.

- Autonomous Mobile Robots (AMRs): Intelligent robots that transport materials throughout the warehouse independently, ensuring a seamless flow of goods without manual intervention.

Together, these systems create a seamless, scalable and continuous flow of operations. They run 24 hours a day, seven days a week, with every technology working in harmony.

Internet of Things: The Smart Brain of Automated Warehousing

If robotics are the muscles of automation, IoT is the brain. Modula’s IoT solutions turn warehouses into intelligent systems that monitor performance, anticipate issues and make real-time decisions.

- Telemetry and Preventive Management: Continuous monitoring that detects potential malfunctions before they cause downtime, improving reliability and efficiency.

- Modula WebAnalytics: A secure, cloud-based platform that provides real-time warehouse data through interactive maps and remote access from any device, enabling complete visibility across multiple sites.

Thanks to OPC-UA, Modula systems integrate easily with existing company technologies. This protocol ensures smooth and secure data exchange across the supply chain without requiring modifications to current systems.

Real Benefits for Industry, Manufacturing and E-Commerce

Smart logistics is already delivering measurable results across key sectors.

- Industry and Manufacturing: Automated warehouses connect directly to production lines, ensuring uninterrupted operations with AMRs and cobots often used as line-side storage and buffers.

- E-Commerce and Online Grocery: Advanced picking systems, AMRs and optimization tools like Modula Optimizer and Plant Designer improve speed and accuracy. Combined with Put to Light or Flexibox solutions, they allow dozens of orders to be fulfilled simultaneously with high precision.

Logistics 5.0: The Future Has Already Begun

The integration of robotics, AI, IoT and automation is not only about efficiency. It marks the evolution toward predictive, connected and sustainable logistics.

This new era transforms the supply chain from a support function into a strategic growth engine. With Modula, this future is already here.

How to optimize picking operations?