Smart warehousing 101: systems, technologies & best practices

Smart warehouses are revolutionising the logistics sector thanks to the integration of connected systems and real-time data analysis. Below are some key points to grasp:

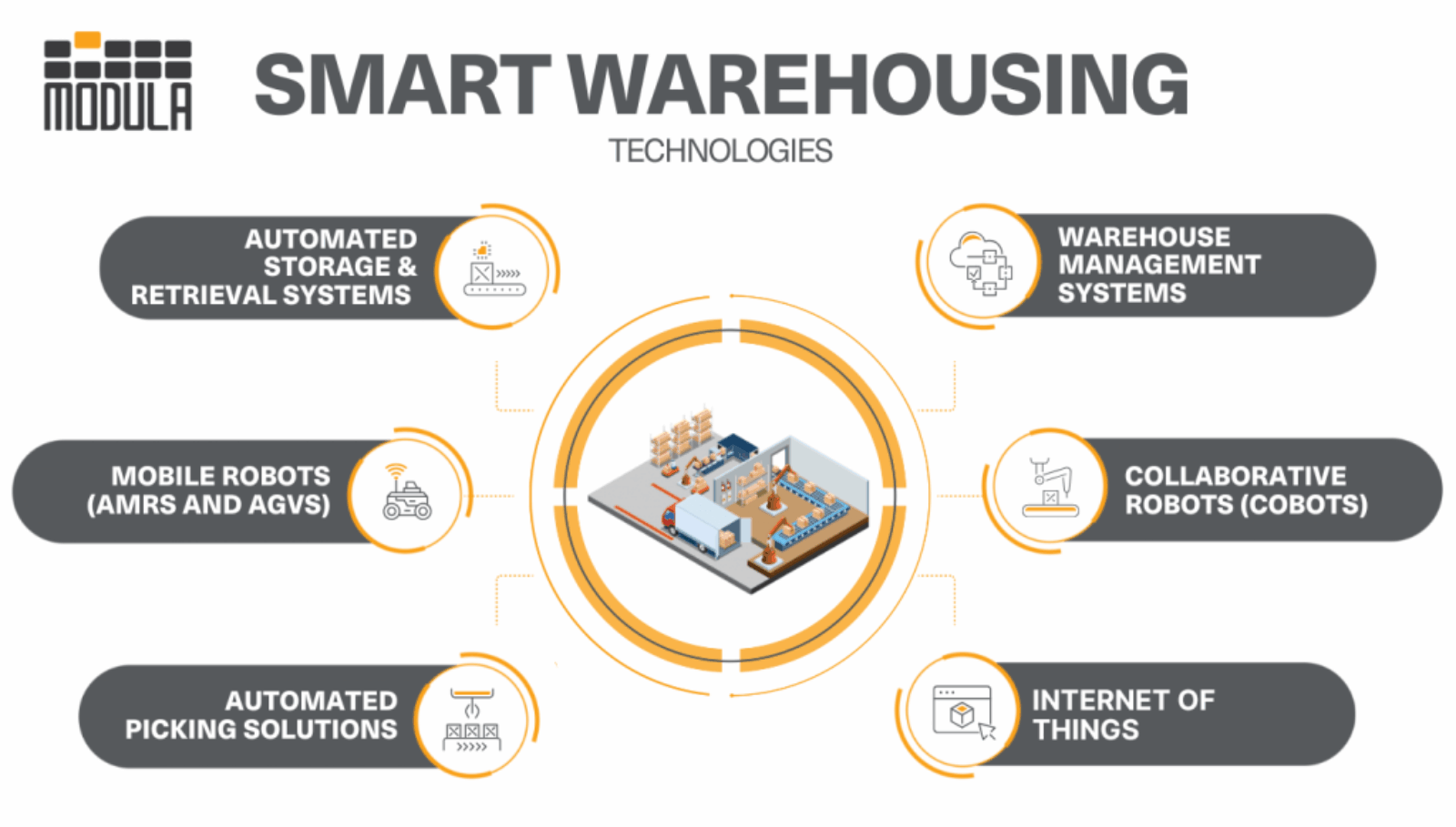

- Smart warehousing combines advanced technologies with warehouse management systems (WMS) to digitize workflows and automate repetitive tasks.

- These solutions include automated storage and retrieval systems, WMS platforms, autonomous mobile robots, collaborative robots (cobots), and automated picking tools.

- With smart warehousing, inventory can be stored more securely, performance data can be accessed instantly, and demand forecasting becomes more precise.

The global smart warehousing sector is projected to reach $75.7 billion by 2032, driven by the expansion of automation, IoT, and data-centric technologies that are revolutionizing warehouse practices worldwide.

From minimizing costly returns through better picking accuracy to reducing the risk of workplace injuries, smart warehousing offers answers to challenges that traditional models can’t effectively address.

In this guide, you will:

- Learn how smart warehouses improve efficiency and provide real-time visibility.

- Explore the core technologies behind smart warehousing.

- Discover proven strategies to run smart warehouses effectively.

- Get to know Modula’s smart warehousing solutions, designed to automate storage and adapt as your business grows.

This resource will equip you with the essentials of smart warehousing and introduce you to Modula’s automated systems, helping you transition smoothly to a smarter warehouse model.

What is a smart warehouse?

A smart warehouse is a facility that relies on automation and advanced technologies—such as automated storage and retrieval systems, robotics, and inventory management platforms—to streamline daily operations.

Beyond automation, a smart warehouse delivers real-time insights and predictive analytics, enabling managers to make better decisions and adapt quickly to shifting customer needs.

Rather than being defined by a single tool or innovation, a smart warehouse represents the integration of multiple technologies working together to optimize every stage of order fulfillment—from receiving goods to getting them to the customer’s doorstep.

Smart warehousing solutions can help you:

- Enhance overall efficiency and boost productivity.

- Keep inventory safe and properly stored.

- Reduce physical strain and risks for warehouse staff.

- Gain complete visibility into stock levels and movements.

Smart warehouse vs. traditional warehouse

Traditional warehouses rely on manual labor and standard storage systems to manage and move inventory. In contrast, smart warehouses incorporate automation and digital solutions.

This shift results in significant improvements: smart warehouses can greatly increase efficiency and throughput, while cutting down on errors in critical tasks like picking, stock management, and packing.

| WAREHOUSE TYPE | SMART WAREHOUSE | TRADITIONAL WAREHOUSE |

| Technology | Leverages automation, IoT devices, and data-driven analytics to optimize operations | Depends on manual workflows and conventional storage racks |

| Inventory management | Employs real-time monitoring and automated stock replenishment | Relies on manual checks and paper-based record keeping |

| Efficiency and productivity | Optimizes workflows and minimizes downtime through automation | Relies on slower, labor-intensive methods with limited efficiency |

| Accuracy | Enhances precision and reduces mistakes in picking and packing | More vulnerable to human errors |

| Labor Dependency | Employees are supported by robotics and automation tools | Operations rely heavily on manual labor |

| Scalability | Can be expanded seamlessly through technology upgrades | Growth potential is restricted and difficult to scale |

6 Key smart warehousing technologies

In smart warehouses, manual processes are replaced with automation, allowing businesses to raise productivity, cut labor expenses, and speed up order processing.

A smart warehouse makes it possible to track stock levels in real time while optimizing operations with advanced tools and automation.

1) Automated storage and retrieval systems (ASRS)

ASRS are computer-driven systems that automatically store and retrieve goods from designated warehouse locations.

Linked with a Warehouse Management System (WMS), they determine which item should be picked at any given time.

Examples of ASRS include vertical lift modules, horizontal carousels, tote shuttles, mini-loaders, and unit-loaders—all designed to maximize efficiency and storage density.

2) Warehouse management systems (WMS)

WMS platforms are software applications that provide real-time visibility into inventory levels and stock movements.

These systems can also integrate with picking solutions to direct operators toward the right items and quantities, reducing errors and speeding up the process.

3) Mobile robots (AGVs and AMRs)

Automated Guided Vehicles (AGVs) are machines that move goods around a warehouse by following fixed paths, often guided by markers or wires, and sometimes requiring human oversight.

Autonomous Mobile Robots (AMRs), the next evolution of AGVs, use sensors and AI to navigate independently without human intervention.

Both AGVs and AMRs transport goods, but AMRs are more advanced and flexible, capable of adapting to their surroundings in real time.

4) Collaborative robots (Cobots)

Cobots are robotic systems designed with sensors and safety mechanisms that enable them to safely work side by side with humans.

They handle repetitive or physically demanding tasks such as palletizing, picking, and packing—improving both productivity and workplace safety.

5) Automated picking solutions

These technologies boost accuracy and speed by guiding staff directly to the right picking locations.

Methods include pick-to-light, put-to-light, and voice-directed picking systems, which minimize human error and streamline order fulfillment.

6) Internet of Things (IoT)

IoT devices in warehouses include smart sensors, scanners, and robots that perform a variety of functions.

They monitor conditions like temperature and humidity, track stock in real time, and assess the performance of warehouse equipment—ensuring smooth and efficient operations.

Smart warehousing brings together advanced technologies like automated storage and retrieval systems (ASRS), autonomous mobile robots (AMRs), and collaborative robots (cobots) to create highly efficient, data-driven operations.

Benefits of smart warehousing

Smart warehouses face pressure to handle more orders, faster, with fewer errors. Smart warehousing addresses these challenges by combining automation, IoT, and software intelligence. The main advantages include:

- Higher picking accuracy and speed

Traditional methods such as manually checking pick tickets are time-consuming and error-prone. With solutions like pick-to-light or voice-directed picking, operators are guided directly to the right items, making it possible to process multiple orders quickly and accurately. - Faster order fulfillment

Automated warehouse systems can work 24/7, boosting throughput and shortening lead times—helping businesses keep up with customer expectations for rapid delivery. - Better space utilization

Technologies such as vertical lift modules and horizontal carousels maximize existing warehouse space, allowing you to use ceiling height and floor width more efficiently and save up to 90% of valuable square footage. - Fewer manual errors

By automating repetitive tasks, smart warehousing reduces mispicks and shipping mistakes. This improves customer satisfaction while lowering costs tied to product returns and rework. - Real-time data visibility

With IoT sensors and warehouse management systems, you gain instant access to critical data such as inventory levels, equipment performance, and stock movement. This transparency supports smarter inventory control and more accurate demand forecasting. - Improved employee safety

Automating hazardous or strenuous activities—like lifting heavy loads or accessing high shelves—protects workers from injuries, ensuring a safer and more ergonomic work environment.

Smart warehousing technologies such as pick-to-light and voice-directed picking make it easier for workers to quickly locate items, improving both accuracy and speed.

Smart warehousing best practices

Purchasing automation tools is just the beginning; the real value comes from successfully embedding them into your daily operations. To maximize your investment and create a high-performing smart warehouse, consider these five best practices:

Rethink Your Warehouse Layout

Bigger isn’t always better. A well-designed floor plan can have a greater impact than extra square footage. Solutions like vertical lift modules and horizontal carousels can free up as much as 90% of usable space compared to traditional shelving.

Use Demand Forecasting

Accurate forecasting helps you prepare for seasonal shifts, special promotions, or sudden spikes in customer demand.

To put demand forecasting into action:

- Collect detailed sales data (by SKU, region, or customer profile).

- Select a forecasting method such as exponential smoothing (weighted averages of past data) or regression analysis (analyzing relationships between variables).

- Continuously update your models to improve accuracy over time.

Prioritize Energy Efficiency

Sustainability isn’t just good for the planet—it also lowers costs. Energy-conscious practices can significantly reduce utility bills and environmental impact.

Examples include:

- Switching to LED lighting, which lasts three to five times longer than traditional bulbs.

- Installing motion-activated lights or skylights to make the most of natural light.

- Upgrading to energy-efficient HVAC systems and ensuring they receive annual maintenance.

Collaborate with a 3PL Partner

Third-party logistics (3PL) providers bring expertise in supply chain optimization and can offer smart warehousing solutions tailored to your needs. If immediate investment in automation isn’t feasible, a 3PL can provide access to WMS platforms, automated picking systems, and other advanced technologies without requiring large upfront costs.

Train Your Workforce

Even the most advanced systems rely on people who know how to use them effectively. Training ensures safety and maximizes ROI.

Practical ways to train employees include sharing tutorial videos, conducting live demonstrations, and offering hands-on practice with new tools.

Modula’s smart warehouse solutions

As a leader in automated storage and warehouse management systems, Modula helps companies across industries reimagine their operations—boosting productivity, accuracy, and overall efficiency.

-

Modula Vertical Lift Modules (VLMs)

Our Vertical Lift Modules are engineered to maximize space utilization by taking advantage of warehouse ceiling height. With a compact footprint and intuitive design, VLMs improve storage density and streamline order picking.

We offer multiple models to suit different operational needs:

- Modula Flexibox: Capable of handling up to 180 bins per hour, it’s designed for fast-moving industries that need high-performance picking with maximum flexibility.

- Modula Lift: The flagship model, Modula Lift can cut floor space requirements by up to 90% while delivering outstanding speed, efficiency, and accuracy in order picking.

- Modula Slim: The smallest VLM on the market, offering advanced storage technology in a minimal footprint—ideal for facilities with space constraints.

- Modula Climate Control & Clean Room: Purpose-built for environments with temperature fluctuations, these systems maintain stable storage conditions and protect products from contaminants.

- Modula Next: A hybrid solution that blends the efficiency of VLMs with the precision and security of industrial vending technology.

Key benefits of Modula VLMs include:

- Save up to 90% of floor space with a compact design that maximizes vertical capacity.

- Process more orders in less time, with throughput reaching 140 trays per hour.

- Increase picking speed to 300+ lines per hour.

- Improve worker safety by removing the need to stretch, climb, or bend to reach items.

- Protect valuable inventory with enclosed, access-controlled storage.

-

Modula Horizontal Carousels (HCs)

For warehouses with limited ceiling height, Modula Horizontal Carousels provide a high-density storage solution that ensures speed and accuracy in order fulfillment.

With our HC systems, you can:

- Adjust shelf spacing to accommodate a wide range of products.

- Achieve high-speed picking rates—up to 550 lines per hour per operator.

- Maintain complete traceability of stock levels and orders.

- Monitor picking activities in real time for better visibility.

- Reach 99% picking accuracy using Put-to-Light systems and barcode scanning.

-

Modula picking solutions

Finding the right product quickly is critical for order accuracy and efficiency. Modula’s picking solutions are designed to minimize search time and increase precision, whether you’re handling single-item orders or large batch picking.

With Modula picking technology, you can:

- Improve speed and accuracy: Light-guided devices direct operators to the correct storage location, ensuring faster and error-free picking.

- Strengthen inventory management: Gain detailed insights into both current stock levels and future inventory needs, enabling smarter planning.

To support these processes, Modula offers a powerful Warehouse Management System (WMS) that provides full visibility into stock location and movement.

You can choose from two WMS options:

- Modula WMS Base: Standard with every Modula automated solution, offering core inventory tracking.

- Modula WMS Premium: A complete, end-to-end solution for advanced inventory control and warehouse management.

Benefits of Modula WMS include:

- Real-time, 360° visibility of all inventory.

- Accurate tracking of stock levels and movement.

- Even greater precision when integrated with Modula ASRS solutions.

-

Modula Web Analytics

Managing warehouse performance becomes easier with Modula Web Analytics, an always-on, built-in solution that connects seamlessly with Modula ASRS. Through an intuitive online portal, you can monitor and optimize your operations securely from any device, anywhere.

Key features of Modula Web Analytics include:

- Remote monitoring: Keep track of your Modula systems without being on-site.

- Proactive management: Access remote diagnostics, technical support, and predictive maintenance tools.

- Operational visibility: Track energy consumption, equipment health, and unit performance metrics.

- Instant notifications: Receive alerts about the status of each machine.

- Detailed reporting: Generate reports on cycles completed, tray utilization, energy usage, and order fulfillment.

By integrating Modula’s automated solutions with Web Analytics, you can create a fully connected smart warehouse that increases efficiency, boosts picking accuracy, enhances inventory management, and optimizes space utilization.

Smart warehousing: frequently asked questions

How does smart warehousing improve efficiency?

Smart warehouses leverage automation to handle order picking, monitor stock in real time, and anticipate equipment maintenance needs.

Artificial intelligence is used to predict demand and fine-tune stock levels, while IoT sensors keep a continuous check on operations.

The outcome: faster order fulfillment, fewer out-of-stock issues, reduced downtime, and lower operational costs.

Which industries benefit most from smart warehousing?

Smart warehousing is being adopted across a wide range of sectors:

- Retail & eCommerce: Supports rapid fulfillment and short delivery windows.

- Pharmaceuticals & Healthcare: Maintains temperature control and enables precise product tracking.

- Automotive: Optimizes storage and facilitates just-in-time production models.

- Food & Beverage: Safeguards perishable goods and strengthens traceability systems.

Third-Party Logistics (3PL): Enhances flexibility and scales seamlessly with customer demand.

How is artificial intelligence applied in smart warehouses?

AI drives multiple functions that increase speed, accuracy, and reliability:

- Demand forecasting: Machine learning models evaluate sales data, seasonality, and market patterns to predict inventory needs.

- Optimized picking routes: AI assigns tasks dynamically and creates efficient travel paths for operators and robots, cutting down unnecessary movement.

- Predictive maintenance: Algorithms track equipment performance, detect anomalies, and schedule proactive repairs to avoid downtime.

Quality assurance: Vision systems powered by AI verify product positioning, identify damage, and check packaging accuracy.

What are the main challenges of adopting smart warehousing?

Although the advantages are clear, organizations often face hurdles during the transition:

- System integration: Connecting new automation tools with legacy WMS or ERP systems can require substantial IT resources.

- Data management: IoT devices, robotics, and AI generate massive volumes of data that demand advanced analytics and reliable infrastructure.

- Scalability: As operations expand, companies need solutions that grow without requiring costly overhauls.

Workforce adaptation: Employees must be trained and supported to collaborate effectively with AI systems and robotics.

How to overcome these challenges: phased implementation, careful planning, and strong collaboration with experienced automation partners are key to successful adoption.

The advantages of a Modula automatic vertical storage system