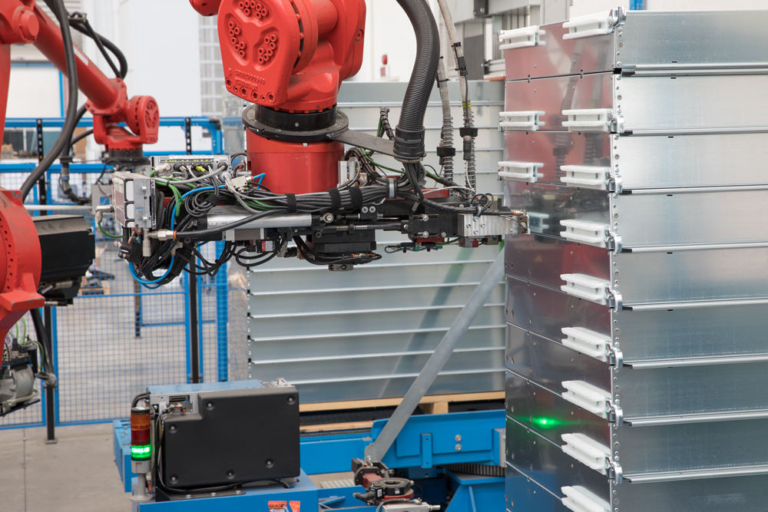

Everything happens automatically. Starting with the cutting of the panels directly from rolls of sheet steel, production moves swiftly through to finished components. The possibility of producing a flow of single parts, kits or batches depends on the specific orders.

Production is managed just-in-time and monitored step-by-step by our special MPS (Modula Production System) software, developed in-house.

This software has been created and implemented not just to manage and plan requirements linked to sales orders, but also to provide full control and overview of the progress of each order via an integrated barcode reader system and connected transport systems. MPS communicates with the Materials Requirements Planning (MRP) and Enterprise Resources Planning (ERP) systems for the automatic scheduling of work requests, which are sent directly to outside suppliers and to internal production facilities to manage the entire production process.

This interconnection with production systems via robots and software allows us on the one hand to reduce costs and increase productivity, but on the other hand to maintain real-time control over the progress of each order. The designs for each of the components that go into our vertical warehouses are sent directly to the machines involved in the production process.