As a future-oriented company, we’re investing in Artificial Intelligence to make warehouse management increasingly efficient, intelligent and predictable.

Modula has integrated advanced technologies to develop new AI-powered tools that allow you to optimise logistics operations and use of space, and anticipate future requirements.

Simulation and Optimisation Tools

Leveraging the latest AI algorithms, Modula offers innovative solutions for

- Simulating warehouse replenishment

- Predicting and visualising how materials will be organised and distributed in automatic warehouses

- Optimising performance with predictive analyses to improve replenishment and picking

- Accurate forecasting

- Improving use of space in every available centimetre, cutting waiting and access times

- Reducing errors and improving your workflow

Presenting two new tools designed by Modula to improve your warehouse and achieve next-level performance!

Analyse and optimise your warehouse management with Plant Designer and Optimizer

To maintain optimal, efficient warehouse management, it’s vital to choose reliable, high-performance solutions: innovative tools that are able to combine hardware and software and ensure seamless integration.

With that in mind, we’d like to introduce you to one of our latest innovations here at Modula: the Plant Designer and Optimizer, developed to plan, simulate and optimise warehouse setups.

What’s Optimizer?

Before we explain Optimizer, let’s take a step back and look at Plant Designer.

Plant Designer is an advanced simulation tool developed by Modula – intended primarily for its Sales Team – the main functions of which include:

- Sizing: To accurately calculate the number of Modula units needed to manage inventory. This allows for adequate warehouse setup, thus reducing waste and optimizing costs.

- Basic tray layout: To design tray layout based on the dimensions and features of the inventory items. The result? Efficient layout for optimal space management.

- Advanced tray layout: This allows you to integrate data about the orders being processed, further optimising tray layout for improved operational efficiency and faster lead times.

- Order simulation: To simulate order fulfilment and management, providing an analysis of operational performance prior to implementation, so you can base your strategic decisions on real-world data.

Plant Designer is a simulation tool that can be used by the Modula team to analyse data about a system

- By importing real-world data from the WMS: This function can create a new project by importing the configuration from an existing system.

- By exporting Data and running a Simulation: In this case, the export function allows us to export data from the system, to simulate a period (date and time); the data are memorised in special encrypted .msim files that can only be read and processed by Plant Designer.

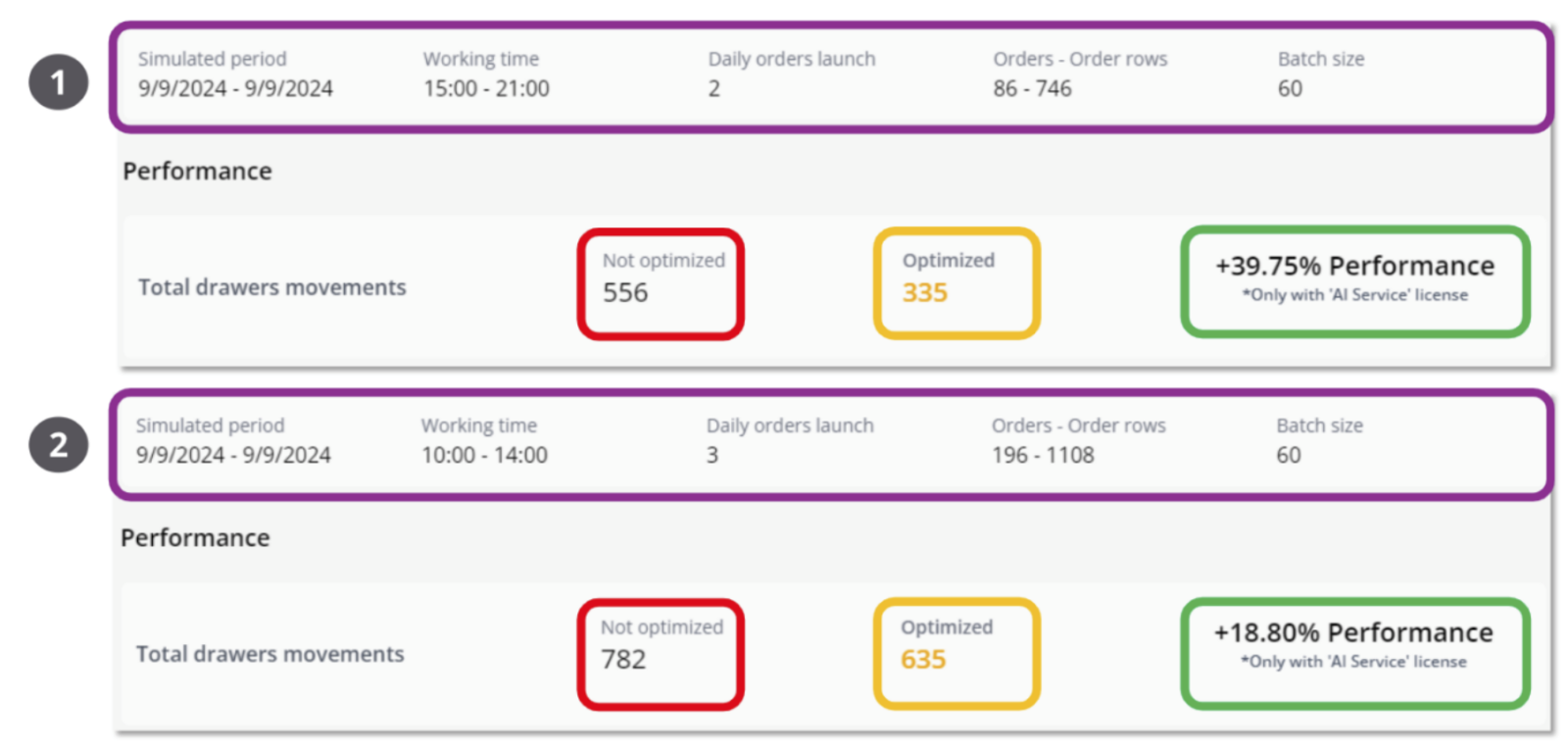

Examples of simulated periods and resulting benefits

Want to find out how Optimizer can optimise your day-to-day operations?

Curious to find out more about this new license? Get in touch: we’ll be delighted to show you all the benefits that Modula can offer your business.

Building on the trailblazing features of Plant Designer, we have also developed the Optimizer tool for our clients: a software license that’s available as an optional package with Modula WMS Premium. Optimizer uses the same scheduling algorithm as Plant Designer to deliver remarkably accurate, tangible results. By using Optimizer businesses can improve order processing in real time, optimising resource distribution and speeding up lead times.

What functions does Optimizer offer?

Optimizer uses two main algorithms to improve SKU storage and picking:

- Replenishment algorithms for:

- Correlating products: Maintains information about correlation between SKUs, creating a map of correlations to determine which SKUs are picked together most frequently.

- Optimising replenishment: Finds the best way to store SKUs according to the correlation map, by placing products that are likely to be ordered together in the same tray.

- Picking algorithms for:

- Scheduling a selection of orders: Selects a group of orders to prepare together, based on the trays involved, according to the current status of the VLMs.

- Optimising order picking: Based on a set of orders that can be prepared together, and the current state of the VLMs, it selects the optimal quantities to pick for each compartment, minimising tray movements.

Other key features:

- Offline activation: The license doesn’t need an internet connection for everyday use, but it does require an annual activation code. This simplified process ensures it runs smoothly without downtime caused by connectivity issues.

- Continuity and scalability: Even if the Optimizer license is not renewed, the standard Modula WMS functions remain available, allowing basic warehouse operations to continue uninterrupted.

How Plant Designer and Optimizer can transform everyday warehouse operations

Although they are two separate tools, Plant Designer and Optimizer work in tandem. Plant Designer can plan and simulate workflows, while Optimizer implements these simulations in a real working context, making optimised workflows an everyday reality for our clients.

This makes it possible to simulate order fulfilment within a specific timeframe and compare the results produced by the new picking and order scheduling algorithm included in the Optimizer license with those from standard algorithms.

And with the latest version of Modula WMS (version 3.11.13.3), Plant Designer has gained additional new functions, such as the option to export warehouse data for detailed simulations of specific periods.

These innovative solutions, devised by Modula, can concretely improve business agility and efficiency. Clients who subscribe to these licenses and tools can reap the benefits of our constant efforts to develop the Modula WMS functions, elevating their logistics management to a whole new level.

Ideas for warehouse reorganization