In an era where agriculture faces increasingly complex challenges, including climate change, resource scarcity, the need for traceability, and food safety, the search for innovative, agile, and technological solutions is more urgent than ever.

Marco Giuliani, a consultant specializing in advanced agricultural systems, explains how automated vertical warehouse technologies can effectively respond to the demands of modern agriculture.

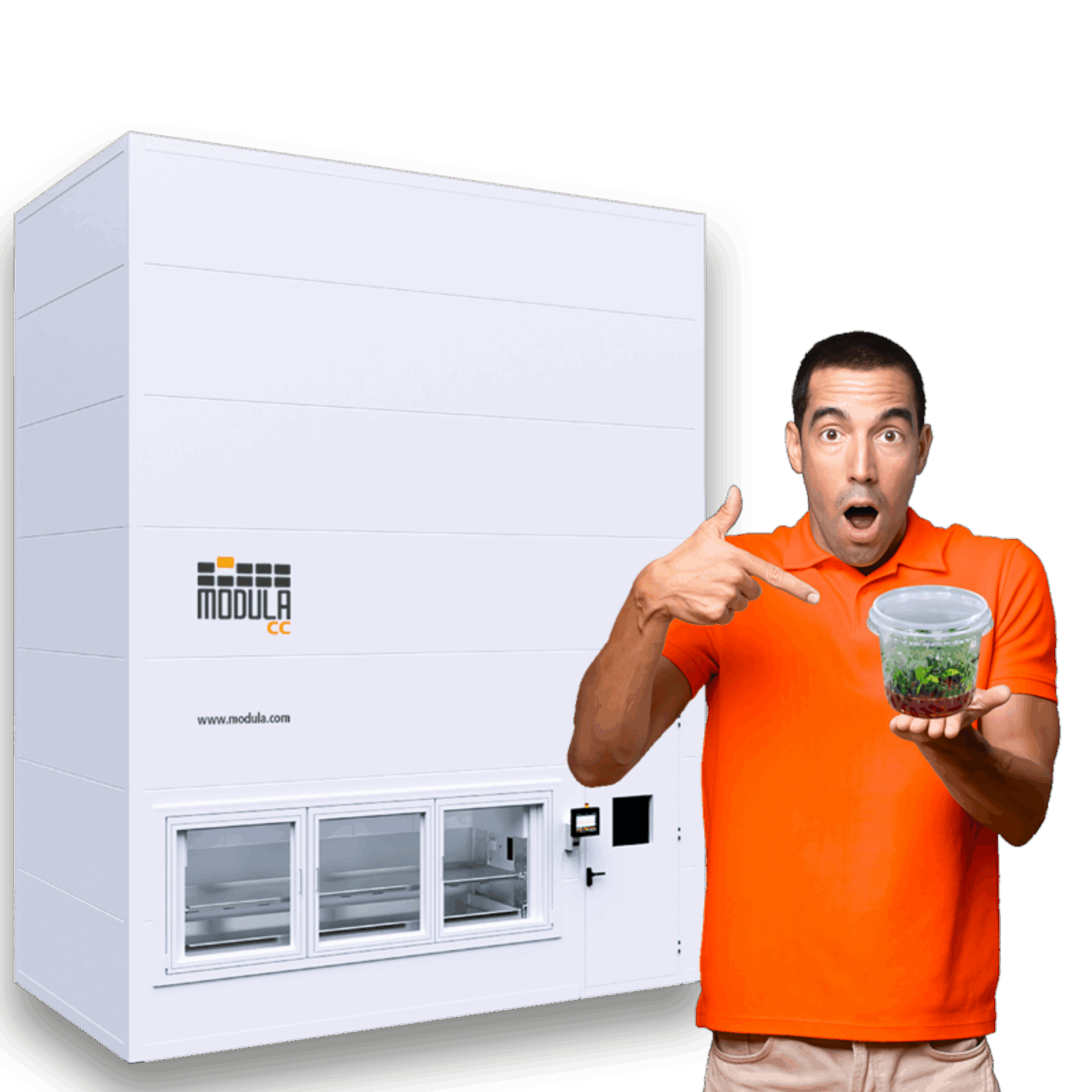

His recent collaboration with Modula, focused on exploring the application of these technologies in vertical farming and other areas, has opened promising new opportunities for a more efficient, controllable, and sustainable production model.

The Needs of Modern Agriculture: Vertical and Smart Solutions

Marco Giuliani, a self-employed agronomist, has long been committed to innovative agricultural practices. His work focuses on micropropagation, hydroponic systems, and advanced plant nurseries, which are areas where agronomic science and technology come together.

As highlighted in a recent article, micropropagation is an essential technique used to produce a large number of genetically identical plants from a small portion of plant tissue. It is becoming increasingly important in plant nurseries, genetic research, and the production of high-value crops.

Manual management of these processes often introduces critical risks such as contamination, inconsistency, and complex spatial or scheduling demands. This is where technology offers meaningful advantages by improving efficiency, repeatability, and resource optimization.

Solutions like the Modula Biotech Tower are intended to bring agriculture into a new era of precision, control, and reliability.

Modula Biotech Tower: innovation for culture in a controlled environment

The Modula Biotech Tower is a fully automated vertical warehouse designed to provide constant, centralized control of temperature, humidity, and lighting. Each stage of the production cycle takes place in a closed, isolated environment that can be accessed without direct contact. This greatly reduces the risk of contamination. In addition, the system ensures complete traceability of every tray, container, pot, or jar.

Initially developed for high-yield vertical farming, the system includes fertigation features, carbon dioxide regulation, and advanced climate management. By optimizing vertical space and digitizing every stage of the process, this warehouse represents a major advancement for micropropagation professionals. It improves not only output quality but also ease of management, system scalability, and production standardization.

More recently, the Biotech Tower became the centerpiece of a collaboration between agronomy specialists and Modula, aimed at developing an indoor strawberry cultivation project. The goal was to evaluate the feasibility of growing leafy and fruit-bearing plants in fully controlled environments.

“The approach proved promising. Modula systems, although originally developed for other industries, also showed their adaptability to vertical agriculture. Most importantly, we recognized their potential for micropropagation,” Giuliani explained.

Following the first strawberry trials, the system was also successfully used to cultivate chili peppers, lettuce, and basil. These results demonstrated that, with the right environmental conditions, the system can be adapted to a wide variety of crops and vertical farming models.

Technological Solutions Ensuring Efficiency, Quality, and Sustainability

The observed benefits, which are both tangible and measurable, can be summarized as follows:

Space Efficiency

- The Modula Biotech Tower saves up to 90% of space compared to traditional solutions by maximizing the use of each cubic meter through vertical construction.

- Vertical structures can reach heights of up to 14 meters (46 feet), maintaining consistent microclimates without heat or cold loss along the column.

- A single Biotech Tower measuring 10 meters in height can manage between 250,000 and 500,000 seedlings, significantly reducing floor space requirements and increasing productivity per square meter.

In practice, a Modula warehouse allows you to grow ten times as much in the same space compared to a traditional greenhouse or farm setting.

Contamination Control and Reduction

- The closed, insulated environment of Modula systems dramatically lowers the risk of contamination.

- In most cases, operators do not need to enter the growing area physically. They interact with the system through a thermally insulated, sealed bay equipped with hinged windows that help preserve sterility.

- The system offers complete control and monitoring capabilities. Each tray or container can be identified and monitored in real time.

- The warehouse undergoes regular ozone cleaning cycles, a sophisticated sterilization method that helps keep the environment free from contamination.

Sustainability and Energy Efficiency

- Energy consumption is lower than that of other indoor cultivation systems.

- The sealed environment maintains stable temperature and humidity using fewer machines and less power, resulting in energy costs of approximately €20 to €25 ($22 to $27) per day.

- Thermo-hygrometric conditions are managed by an integrated system that includes an Air Treatment Unit (UTA), a dehumidification module, and an external chiller (usually provided by the client), all of which contribute to precise and automated climate control.

- Lighting optimization reduces energy usage for illumination by up to 50%.

Higher Yields and Time Optimization

- The Biotech Tower reduces waste and enhances the quality of in vitro crops, increasing yields by up to 25% and ensuring uniform plant development.

- Each production cycle can be shortened by as much as one week, which saves time and energy while further improving both productivity and sustainability.

- Overall production efficiency is estimated to be 25% higher than conventional standards.

Real-Time Traceability and Continuous Crop Monitoring

The Modula system clearly provides total control and complete traceability throughout the entire production process.

“Each tray or container can be identified and monitored in real time,” confirms Marco Giuliani.

Operators always know where action is needed, how to respond, and when to intervene. This makes the process transparent, repeatable, and safe. Advanced sensors continuously monitor environmental conditions and automatically trigger corrective actions if any values fall outside the optimal range.

With the Modula Biotech Tower, every phase of production is monitored and managed in real time. This includes climate parameters, crop health, batch traceability, and inventory control. The result is a highly transparent and reliable system for managing both processes and materials. Agricultural operations and research laboratories involved in large-scale in vitro propagation gain substantial advantages from this level of control.

This approach offers maximum reliability and full visibility into every critical variable, delivering meaningful benefits to agricultural enterprises and scientific institutions alike.

“Biotech Tower,” says Modula, “is not just a technological solution, but a true paradigm shift in micropropagation management. It combines productivity with significant improvements in quality and safety, which have a direct impact on business competitiveness.”

A Replicable System for Nurseries, Labs, and Agro-Industries

While micropropagation remains the primary use case, the versatility of the Biotech Tower extends to several other fields:

- Mushroom cultivation

- Intensive insect farming for protein production

- Traditional sectors such as nursery farming and seed selection

The main advantage in all these applications is the ability to create a fully controlled and repeatable environment, which significantly reduces the risk of errors and inconsistencies.

A New Modula Ecosystem: Toward a Scalable and Sustainable Agricultural Future

With the introduction of technologies such as the Modula Biotech Tower and Modula Climate Control, a new model of agriculture is emerging that is scalable, precisely managed, and highly efficient. From micropropagation to insect farming, these solutions bring order, efficiency, and consistency to every stage of the agricultural process.

According to Marco Giuliani, the agriculture of the future will be fully automated and optimized in every dimension, including space, time, and energy.

“It is a technical challenge, but also a cultural one. Vision and courage are required to invest in a new production model.”

This forward-thinking approach is well suited to both large agro-industrial operations and specialized niche producers. The goal is to achieve maximum efficiency and quality in enclosed, controlled, and sustainable environments.

New Technologies for Agricultural Production

Innovative automated vertical warehouses and advanced climate control systems are essential for improving efficiency and sustainability in modern farming.

Download our PDF to discover how these solutions can transform agricultural production.