• A large, reliable, cutting-edge company.

• A conscientious, helpful company, with excellent assistance and prices in line with the market.

• A quality company with a widespread sales network.

• A great company that helps to improve warehouse management.

• A business that has taken forward this kind of machine – very important in our sector – in this country. I consider the company and product to be very reliable.

• An Italian company, recognisable for its aesthetics, which has enabled us to make a game change.

• A state-of-the-art plant, a structured, growing company that is attentive to the needs and customisations that clients demand.

• A company that produces high-performance vertical warehouses.

• Conscientious company with excellent expertise on this type of product, with very effective after-sales service.

• A modern company that is investing to improve products and processes, and to maintain competitiveness.

• It is a company I would recommend, which respects the commitments it makes, and has a product that meets my requirements.

• A good company that helps us with delivery and after-sales. We have very good relations, and they offer good value for money.

• A safe and efficient system, which helps to save a great deal of space.

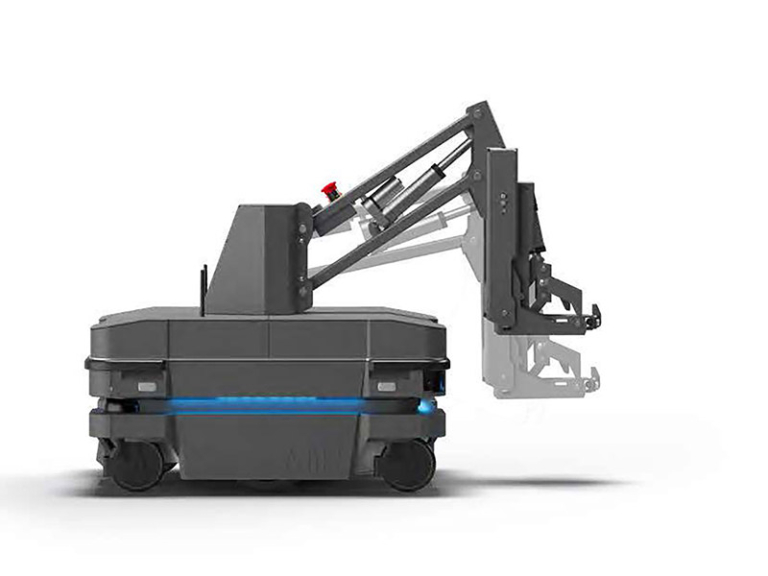

• Convenient and very useful machine, especially for handling small items.

• A great warehouse, where everything comes in one machine.

• A leading company in the field of vertical warehouses.

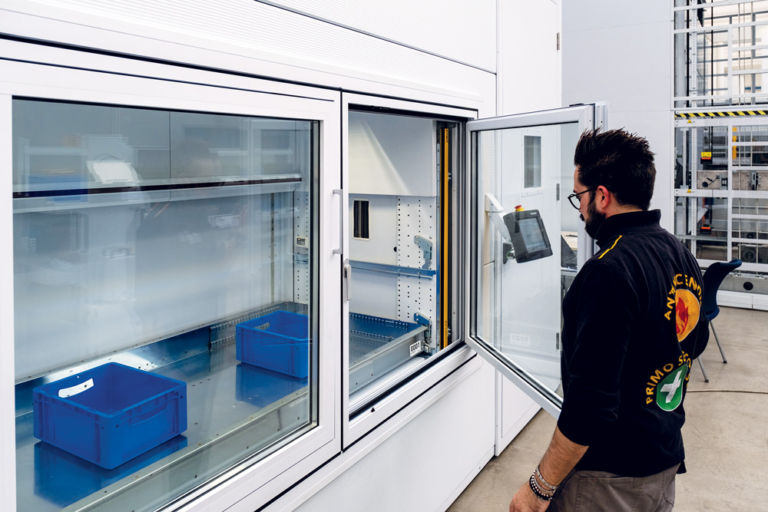

• A product that is simple in its construction (automatic drawers), with a straightforward but effective technology. The advantage is in management.

• A machine that can efficiently manage everything you put inside it. It handles picking and drop-off, so it can manage stocks automatically, without having to go and remove or add items manually all the time.

• An automatic warehouse system that lets you manage a volume of materials that it would be difficult to otherwise, due to the need to handle small or fragile items.

• Excellent use of a warehouse to save space and manage everything in a more functional way.

• A product that has been well thought out in terms of the mechanics and software.

• A good solution if you need space and speed.

• Even someone who has just joined the company can manage the Modulas.

• If there are any issues, just call them or they come and see you on-site.