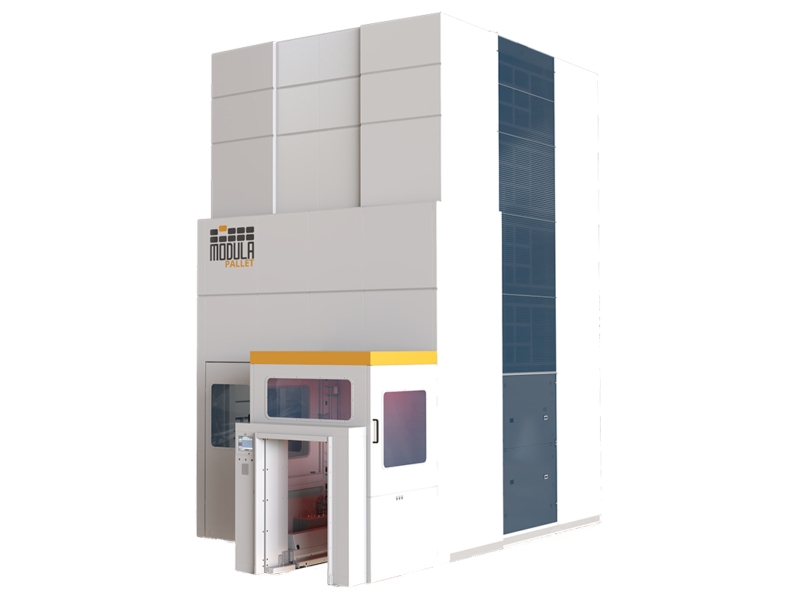

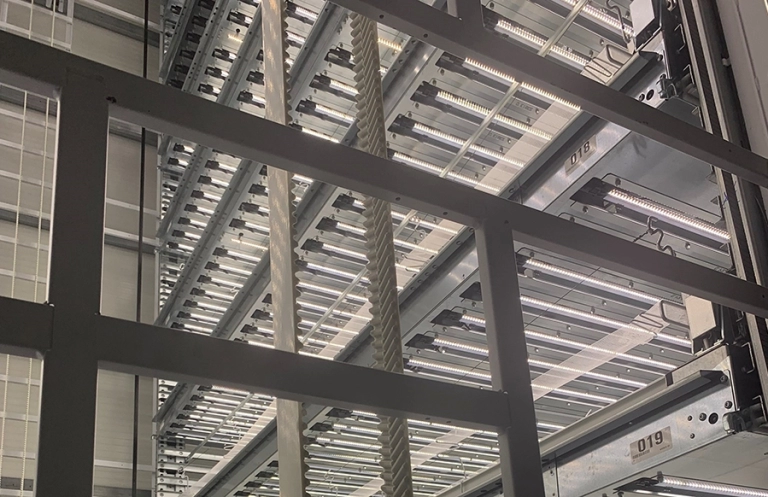

Modula automatic vertical warehouses have the great advantage of optional configuration of the height, size of the tray and bay, load capacity and number of trays and workstations, down to the details of single trays that can be customised with partitions and dividers.

The Modula storage and picking system can be equipped with additional options for automated vertical warehouses, to make picking more efficient, to make picking and order preparation more efficient, help the operator while picking and refilling, carry out other processes in a more linear way or even improve performance and consumption.

That’s why Modula automatic tray storage solutions are ideal for your business.