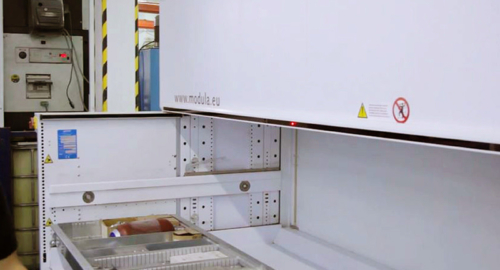

Some companies have placed their Modula warehouse at the heart of their production process, allowing it to set the rhythm of the assembly process and management of production orders. In this way, the company is aware of, and has precise control over, the available quantity of raw materials, in real time. Used correctly, a Modula warehouse can help you avoid starting production and then having to interrupt it again due to a lack of materials.