The medical and pharmaceutical sector, one of the most strictly regulated fields across the globe, can greatly benefit from automated warehouse management solutions like those developed by Modula, as they optimize:

- the flow of data and information to ensure traceability

- the flow of goods to monitor and control shelf life

- the storage volume in the warehouse

- operating costs.

This was also widely proven during the COVID-19 pandemic; medical and pharmaceutical companies that had already implemented automation and digitalization solutions in their warehouses reacted better to the market shock.

Modula’s automated storage systems and the needs of the pharma industry

The automatic storage solutions developed by Modula can be adapted to the specific needs of the medical and pharmaceutical sector, thanks also to digital devices and management software – such as the proprietary WMS – which enable the company to provide a comprehensive, modular product range.

Modula WMS is the warehouse management software that, via an intuitive PC interface, allows for real-time inventory management and can be integrated with any type of company ERP. This integrated approach is very important, as it avoids interruption of information flows while further enhancing the efficiency and precision required by the medical and pharmaceutical sector.

Modula WMS ensures the traceability needed in any warehouse but is at its best when used in conjunction with the Modula automated storage systems.

In particular, Modula’s vertical storage systems for the pharmaceutical sector have the following advantages:

- Optimization of the space available in the warehouse, thanks to the Modula vertical storage systems that reach storage heights of up to 16 metres and are equipped with an automatic system for optimizing space occupation according to SKU size.

- Maximum safety and quality, thanks to the closed tray system that ensures the safe and clean storage of goods. All the units are password protected and can be accessed by authorised personnel only, while the security level can be defined down to each individual tray. With the adoption of user authentication devices, security and accuracy can reach the levels required by the medical and pharmaceutical sector.

- Correct storage of special products, thanks to specific solutions such as Modula Climate for temperature and humidity controlled warehouses, Modula Dry for low humidity warehouses, and Modula Clean Room.

Modula’s automatic vertical storage systems, therefore, perfectly meet the specific requests of the pharma sector, which is why important companies have already successfully adopted our advanced logistics solutions and installed systems that are tailored to their needs.

Modula and the hospital sector

Among the most successful applications of Modula’s automated storage systems for the hospital sector, where hygiene standards must be very high, are the projects developed for the Lille Hospital in France, the Xi’An Hospital Complex in China and the Saint Philibert Hospital, also in France.

These hospitals have chosen Modula’s vertical storage systems for safe and controlled handling and storage of sterilised medical and surgical devices, thus guaranteeing high safety standards and establishing themselves as leading international health care facilities.

They decided to install the Modula automated storage systems instead of other warehouse solutions such as carousels because they offer:

- increased storage capacity

- improved performance

- the possibility to work on opposite bays at the same time.

Modula and the cosmetics industry

Two other successful case studies can be found in the cosmetics industry, where Modula’s vertical storage systems enabled Solimé and Symrise to solve critical issues in the management of their warehouse logistics.

Solimé, a herbal products company, optimized its organisation with 3 Modula Lift systems, 2 for e-commerce products and one for raw materials in the production area. Symrise, a perfume company, reduced the operating costs of its laboratory in New York by managing the same number of SKUs in a smaller warehouse thanks to Modula’s vertical storage systems.

Modula and the pharmaceutical industry

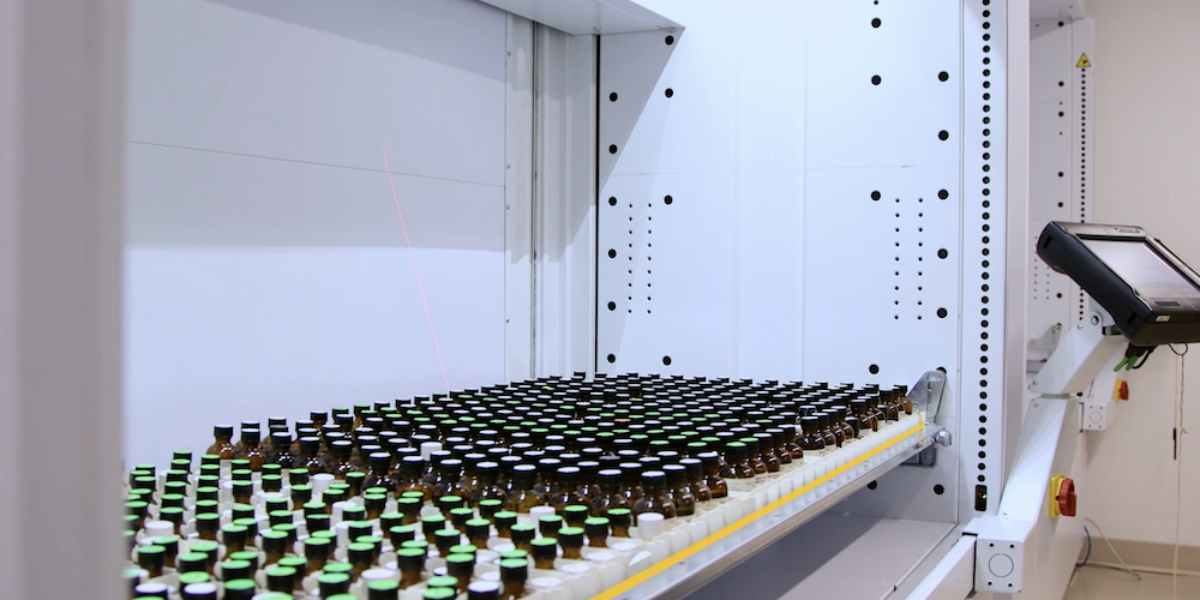

In the pharmaceutical industry, Modula’s automated storage systems are successfully used for both the management of raw materials for production and the storage of finished products.

An example of the first case is Intas Pharmaceuticals, a company based in India which, thanks to the Modula storage systems, has optimized the management of the storage space for small parts and improved security for its high value-added moulds. Gland Pharma, a manufacturer of medical supplies, has also successfully adopted the Modula Lift systems to manage and store the huge number of labels to be affixed to its products, also optimizing storage density thanks to the Modula tray dividers and separators.

Successful examples of the second case include Orfit, a company operating in the sector of thermoplastics, which with Modula Lift increased the number of processed orders from 40/hour to 220/hour, eliminating picking errors and thus successfully responding to the increase in demand. On the other hand, Innomed, a manufacturer of orthopaedic surgical instruments, with the adoption of the Modula automatic vertical storage systems increased the number of items stored by exploiting the vertical space and made picking more ergonomic for its staff.

Modula special solutions

As mentioned above, Modula has also developed special solutions for sensitive goods, such as those handled in the medical and pharmaceutical sectors. They have been successfully chosen by major companies such as Biotec and Coster.

Biotec, which operates internationally in the field of pharmaceutical products, has improved the storage conditions in its warehouse by adopting Modula Climate Control, while at the same time keeping picking operations quick and simple thanks to the Copilot Console. Coster, an Italian multinational manufacturer of aerosol valves, spray actuators, etc., chose Modula’s clean room solutions. In this case, the Modula systems have a double bay with a lower section where the material is loaded and an upper section where it is picked directly from the clean room for production.

Improve your warehouse operations with Modula solutions for the pharmaceutical sector

The companies in the medical and pharmaceutical sector that chose automated storage systems assisted by other digital and technological solutions, also developed by Modula, solved many critical issues and managed to implement custom-made solutions.

If you, too, wish to optimize your warehouse management, increasing efficiency and safety in the storage of your products – including special and high value-added items – contact us for a personal consultation.

Want to know more?